The Art and Science of Bowmaking

The Trade-off Between Playability and Tone

Bow performance can be described by two qualities - Playability (balance, controllability, articulation) and Sound Quality (tone color and its shaping). However, it is virtually impossible to achieve high values for both qualities in the same bow, there is always a trade-off. Just as a car cannot simultaneously have race performance and a smooth, quiet ride, each bow is a compromise between playability and tone quality.

Bow performance can be described by two qualities - Playability (balance, controllability, articulation) and Sound Quality (tone color and its shaping). However, it is virtually impossible to achieve high values for both qualities in the same bow, there is always a trade-off. Just as a car cannot simultaneously have race performance and a smooth, quiet ride, each bow is a compromise between playability and tone quality.

The challenge faced by the modern bow-maker is to achieve an acceptable balance between playability and tone quality, appropriate to the skill level and tastes of the individual player. Players of lesser skill prefer a bow that is easy to handle and will not get them into too much trouble. These players often gravitate to carbon fiber bows, which in general, "handle" very well, but do not have the quality of sound of Pernambuco. Expert players however can compensate for handling idiosyncracies and typically choose the bow that can produce superior tone.

Revealing the Action of the Bowed String

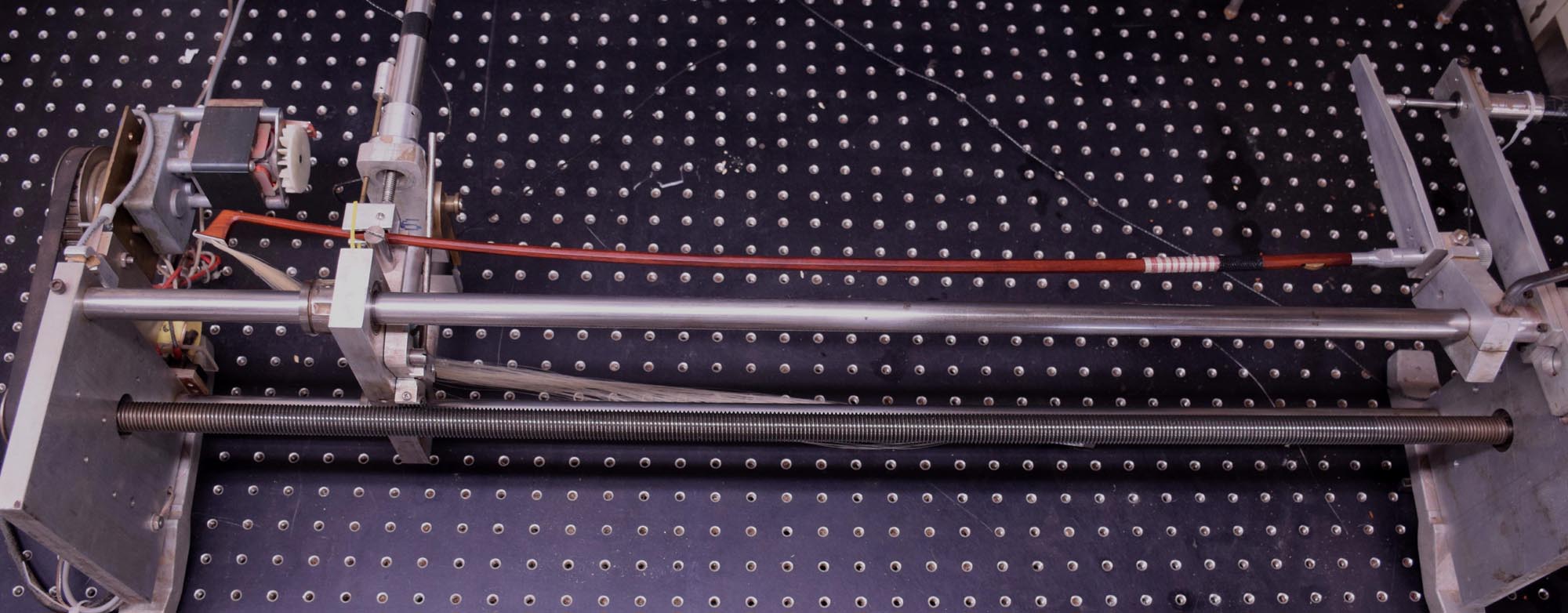

A mechanical bowing machine is used to study how the string responds under controlled and repeatable conditions (bow speed, pressure and distance from bridge), which would be impossible to achieve manually even with expert players.

This machine has demonstrated, among other things, that pressing down harder on the string does not increase volume (but makes the tone harsher). Increasing the bow's speed is a far more effective way to increase sound output. The figure below shows how the string moves side to side for several bow speeds - the classic "stick-slip" response (a.k.a sawtooth or N-wave) of the string.

Click here to see the complete research paper.

Click here for an amazing slow motion video of string motion.

Scientific Measurements Guide Traditional Construction Techniques

Bow design is further complicated by the use of the traditional material - Pernambuco. This increasingly rare, rain-forest wood possesses a unique combination of high stiffness, density (sinks in water) and low damping that makes it ideal for bow-making. No two bows are exactly alike because each piece of wood is different. Two bow blanks cut from the same board can easily vary by 10-20% in their material properties. Therefore each bow must be hand-made and individually tuned to achieve optimal performance. I perform measurements of density, elastic modulus, stiffness, natural frequency, camber and diameter throughout the process of carving a tapered bow from a flat board, using traditional bow-making techniques.

Diameter and Camber are Precisely Controlled

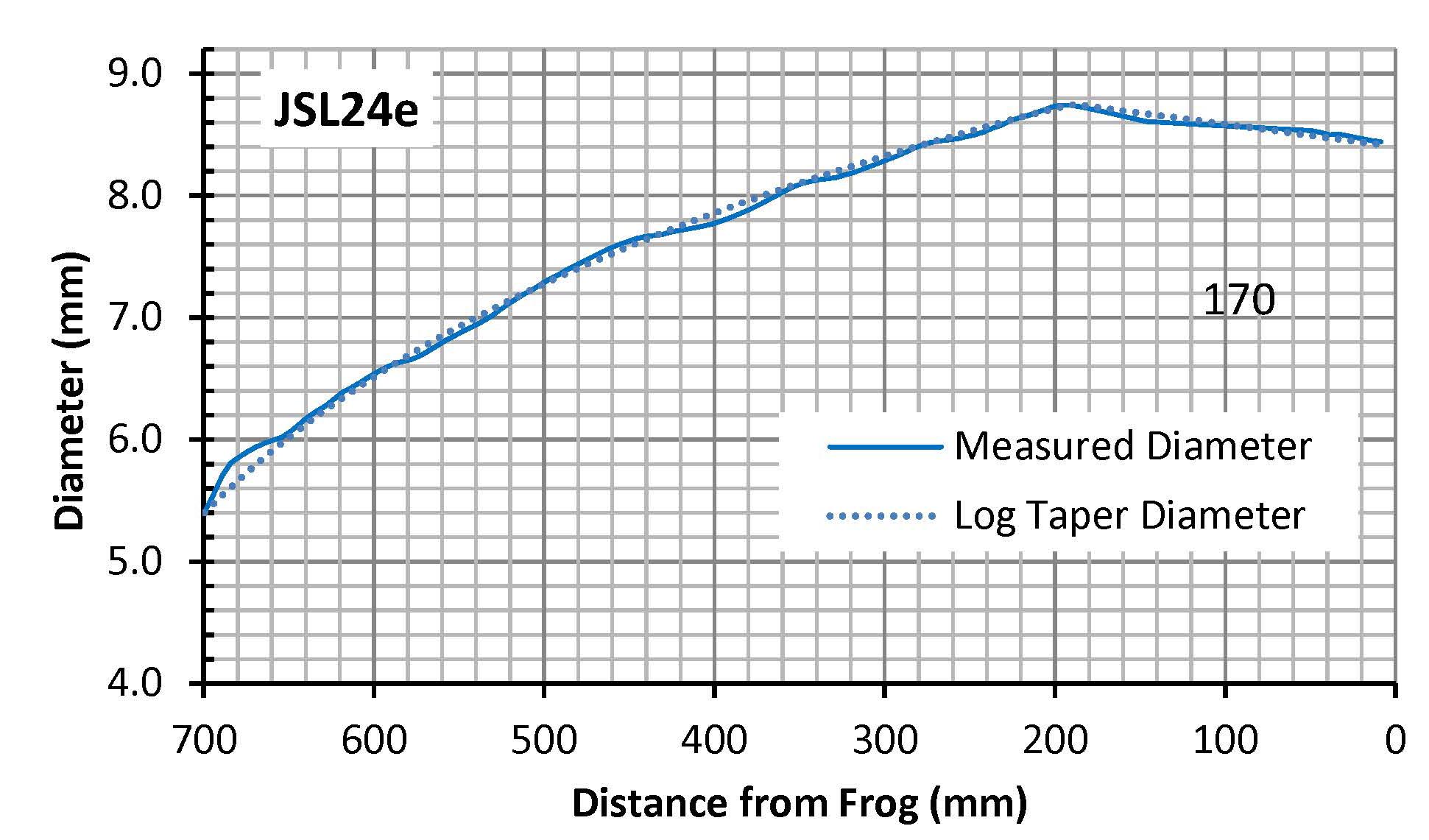

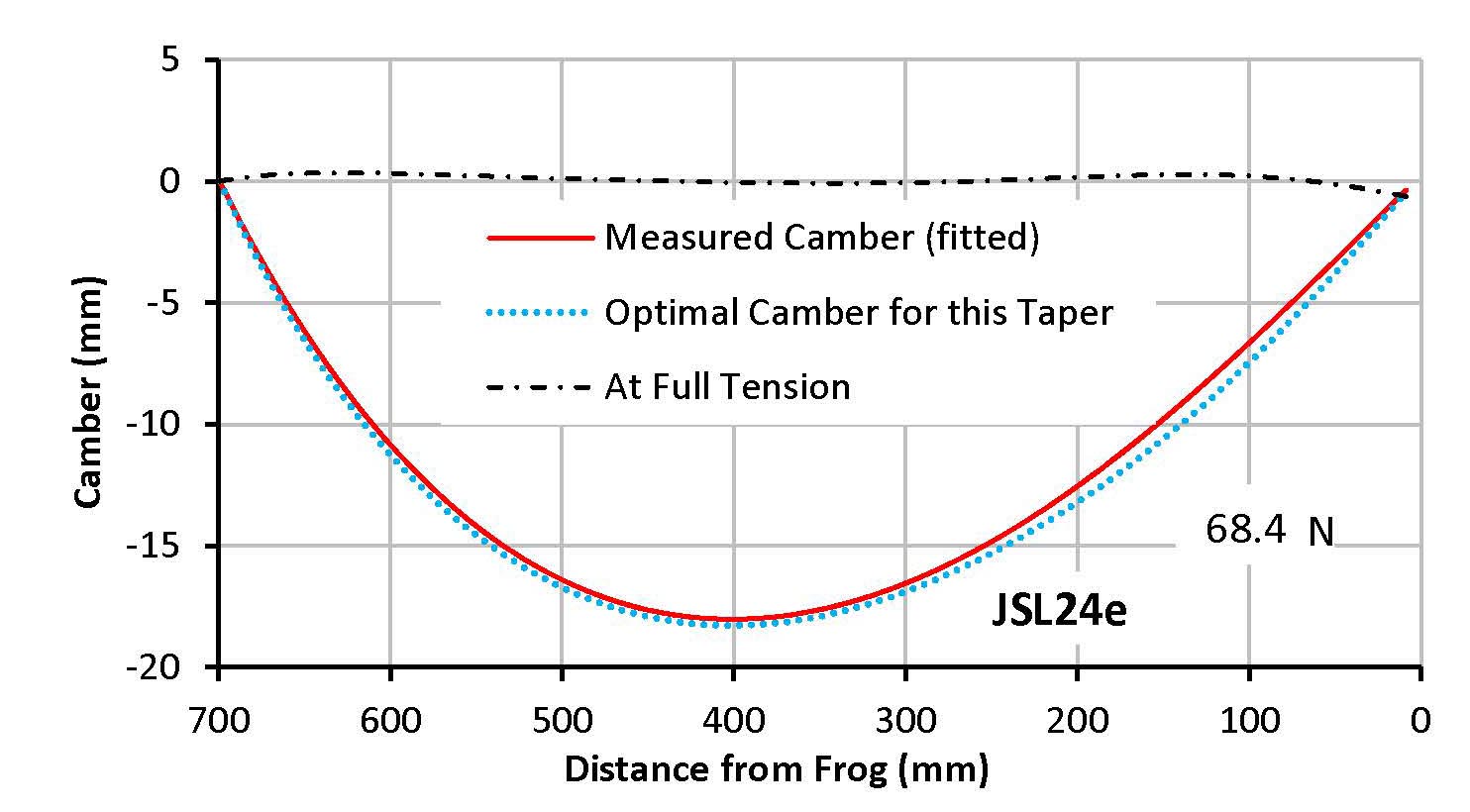

A digitizer, made by Norman Pickering, is used to precisely measure camber and diameter over the length of the bow.

This machine enables matching of camber and diameter to achieve minimal weight and maximum stiffness. Subsequent calculations then predict bow shape under full tension. Historically significant bows by Tourte, Pajeot, Peccatte, Simon, Sartory, Henry and Kittel have been measured for use as design models.

Shown below are measurements and calculations of the bow I made for Bruce Molsky.